- Ameya360 Component Supply Platform >

- Trade news >

- Foxconn Invests $10B in U.S. LCDs

Foxconn Invests $10B in U.S. LCDs

Hon Hai Precision, the parent company of Foxconn, will spend $10 billion to build in Kenosha, Wisconsin a 10.5-generation LCD plant for 8K displays. The deal brokered by the Trump Administration includes $3 billion in tax breaks to create at least 3,000 Foxconn jobs in the U.S.

“TV was invented in America, but it does not have a single fab to produce a single 8K system--we are going to change that,” said Foxconn chairman and founder in a White House event. “We are committed to build the most advanced 8K ecosystem in America — the most advanced in the world,” Gou said.

The deal includes a 20 million square foot Foxconn campus that could ultimately create up to 13,000 Foxconn and 22,000 indirect jobs. The Foxconn jobs will have an average annual salary of $53,000 plus benefits, said Wisconsin Governor Scott Walker.

“This is a great day for anyone who believes in the label ‘Made in the USA,’” said President Trump.

Separately, President Trump told the Wall Street Journal that Apple chief executive Tim Cook promised to build three manufacturing plants in the U.S. The Foxconn LCD fab is not related to Apple, but is focused on LCDs for large-screen TVs.

Analysts described the Foxconn plan as ambitious given the supply chain required to make large LCDs is almost entirely in Korea and China. However, North America is the largest market for large-screen TVs of 55-inches and above, said Ken Werner, a veteran display analyst with Nutmeg Consultants (Norwalk, Conn.).

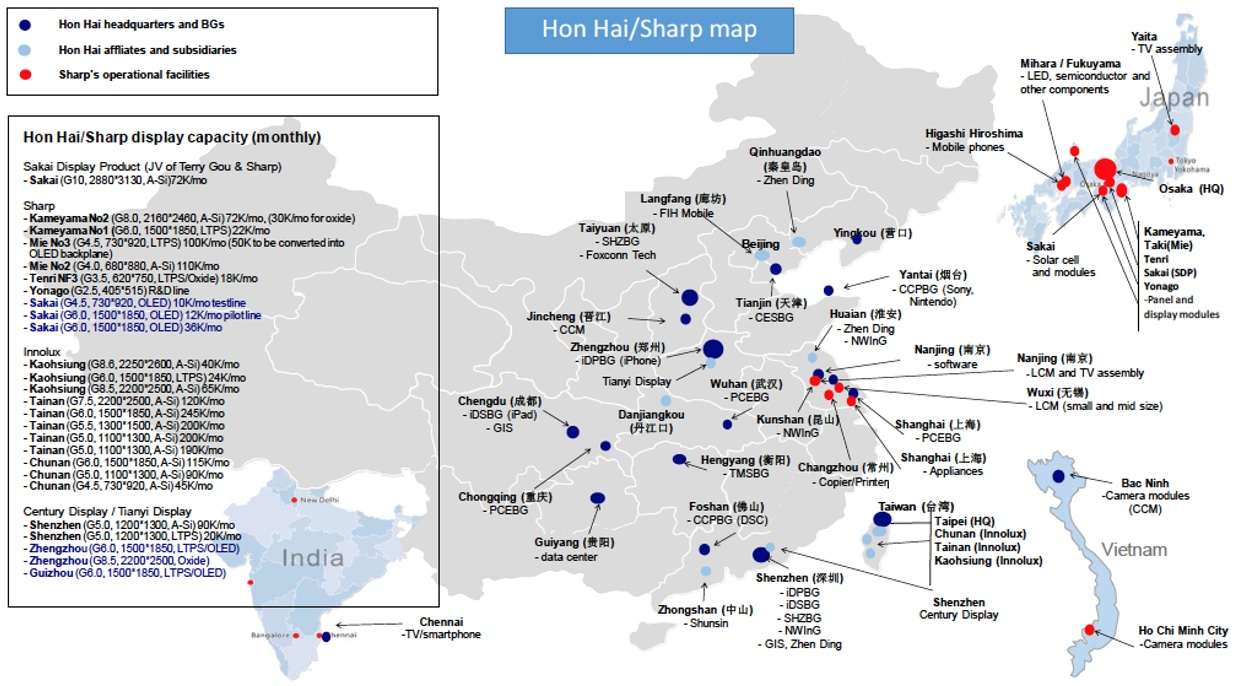

Since it bought Sharp a year ago for $3.5 billion, Foxconn has been trying to revive Sharp’s branded TV business, which the Japanese company sold to China’s HiSense in 2015. HiSense and other TV makers in China, such as TCL and Skyworth, have leapfrogged Sharp and many other TV giants in Japan. Sharp once dominated the flat-panel business but now only Sony remains among top players from Japan.

Large screen displays and to a lesser extent the TVs they go into are cyclical and highly automated businesses typically based on large volumes and thin profits, said Werner. While LCD and TV makers have reaped good profits in the last two years, the business is known for quick up and down swings, he said.

Online messageinquiry

Foxconn Reportedly Readies Chip Fab in China

- Week of hot material

- Material in short supply seckilling

| model | brand | Quote |

|---|---|---|

| CDZVT2R20B | ROHM Semiconductor | |

| BD71847AMWV-E2 | ROHM Semiconductor | |

| MC33074DR2G | onsemi | |

| RB751G-40T2R | ROHM Semiconductor | |

| TL431ACLPR | Texas Instruments |

| model | brand | To snap up |

|---|---|---|

| TPS63050YFFR | Texas Instruments | |

| BP3621 | ROHM Semiconductor | |

| BU33JA2MNVX-CTL | ROHM Semiconductor | |

| ESR03EZPJ151 | ROHM Semiconductor | |

| STM32F429IGT6 | STMicroelectronics | |

| IPZ40N04S5L4R8ATMA1 | Infineon Technologies |

- Week of ranking

- Month ranking

Qr code of ameya360 official account

Identify TWO-DIMENSIONAL code, you can pay attention to

Please enter the verification code in the image below: