- Ameya360 Component Supply Platform >

- Trade news >

- What’s aluminum PCB?Structure of aluminum PCB

What’s aluminum PCB?Structure of aluminum PCB

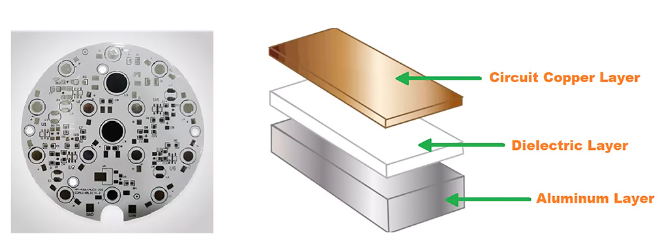

PCB (printed circuit board) with copper layers on one side and aluminum on the other is commonly referred to as aluminum PCB (or the most widely used PCB). The dielectric between these two layers makes it different from the traditional copper foil-based PCBs and a good heat dissipator.

If we zoom into its structure, the aluminum PCB is just a thin metal sheet with holes punched into them. These holes are where the components go—the contacts between the circuit board and whatever device it’s connected to.

Structure of aluminum PCB

Components that make aluminum PCBs are copper, aluminum, and an insulator.

The copper is what makes up most of the board’s mass, and it conducts electricity efficiently.

The aluminum is where current flows through the board, and it helps to create a solid connection between the copper and the insulator.

Finally, the insulator prevents short circuits from forming between these pathways.

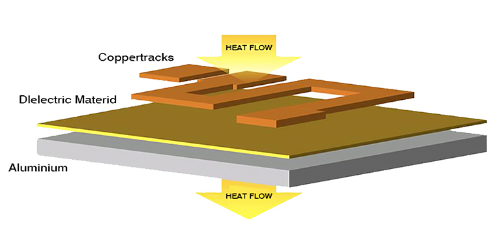

This PCB flows heat away from the system by conducting it away from the area where you want to keep it.

Here, aluminum conducts heat rapidly, so it’s great at conducting away heat. While copper conducts heat slowly but more efficiently than aluminum, so it can help transfer more heat at once. Insulation is used to prevent electrical shorts when a lot of current flows through a circuit.

What are the types of aluminum PCBs?

Through-hole aluminum PCBs

They are made of a large number of through holes drilled into the board. The holes make it easy to connect different parts of the circuit together without having to rely on soldering connections between each piece of electronic equipment that you need to connect together.

Flexible aluminum PCBs

They are known for providing excellent electrical insulation, thermal conductivity, and exceptional flexibility. They are used in applications that require flexibility, such as circuit boards that need to bend easily.

Multilayer aluminum PCBs

Multilayer aluminum PCB is made of multiple layers of materials, such as epoxy resin, which allows for greater protection against corrosion and wear from vibration than conventional lead-free solder joints could achieve on their own.

Hybrid aluminum PCBs

Hybrid Aluminum PCB is made from two different types of materials: one layer is made out of copper foil, while the other layer is made out of aluminum foil. These boards are often used for circuit boards that require both conductors and insulators.

Benefits and limitations of aluminum PCBs

Benefits of aluminum PCBs

Excellent thermal conductivity: makes it ideal for dissipating heat from high-power components, such as in LED lighting and power supplies.

Durability and reliability: make them suitable for a wide range of applications, including in harsh environments.

Cost-effective: generally less expensive to produce than traditional PCBs.

Lightweight: ideal for applications where weight is a concern, such as in aerospace and automotive electronics.

Limitations of aluminum PCBs

Aluminum PCBs offer few design options than traditional PCBs.

Has a higher electrical resistance which can cause issues with signal integrity and high-speed circuits.

Limited availability of design software and manufacturing capabilities.

Due to aluminum PCB heat dissipation ability, it is a useful part of different electronic applications. But the most common are:

High-power LED lighting

Automotive electronics

Power supplies

Telecommunications equipment

Industrial control systems

Medical devices

Military and aerospace applications

Electronic components are attached to aluminum PCBs in the above applications because the metal provides a stable and thermally conductive surface.

How is an aluminum PCB manufactured?

The process of manufacturing an aluminum PCB typically involves several steps.

First, a layer of thermally conductive material, such as ceramic or metal, is bonded to the aluminum base using a high-temperature adhesive.

Then, a layer of insulating material, such as epoxy or polyimide, is applied over the thermally conductive layer to provide electrical isolation.

Next, the PCB is drilled with holes to accommodate the electronic components that will be mounted on it.

Finally, the PCB is coated with a solder mask layer and printed with the desired circuit pattern using a photolithography process.

Manufacturing of this type of board is referred to as metal-core printed circuit boards (MCPCB) in which metal is used as a base of the product.

Challenges and solutions in aluminum PCB manufacturing

One of the main challenges is ensuring that the thermally conductive layer is properly bonded to the aluminum base. To address this challenge, manufacturers must carefully control the temperature and pressure of the bonding process to ensure a strong and reliable bond.

Another challenge in aluminum PCB manufacturing is drilling holes for electronic components. To overcome this challenge, manufacturers can use specialized drilling equipment and techniques, such as laser drilling or micro-drilling, to create precise and high-quality holes in the PCB.

Online messageinquiry

- Week of hot material

- Material in short supply seckilling

| model | brand | Quote |

|---|---|---|

| CDZVT2R20B | ROHM Semiconductor | |

| MC33074DR2G | onsemi | |

| TL431ACLPR | Texas Instruments | |

| RB751G-40T2R | ROHM Semiconductor | |

| BD71847AMWV-E2 | ROHM Semiconductor |

| model | brand | To snap up |

|---|---|---|

| TPS63050YFFR | Texas Instruments | |

| ESR03EZPJ151 | ROHM Semiconductor | |

| BU33JA2MNVX-CTL | ROHM Semiconductor | |

| BP3621 | ROHM Semiconductor | |

| IPZ40N04S5L4R8ATMA1 | Infineon Technologies | |

| STM32F429IGT6 | STMicroelectronics |

- Week of ranking

- Month ranking

Qr code of ameya360 official account

Identify TWO-DIMENSIONAL code, you can pay attention to

Please enter the verification code in the image below: