Panasonic Industry Commercializes Conductive Polymer Tantalum Solid Capacitors (POSCAP) with The Industry's Lowest Profile*1 to Support High-Output Power Delivery Required for USB Type-C Connections

Panasonic Industry Co., Ltd., a Panasonic Group company, announced that it will begin commercial production of its two models of Conductive Polymer Tantalum Solid Capacitors (POSCAP), 50TQT33M and 63TQT22M. These capacitors are incorporated into power circuits used for information and communication equipment, including laptops and tablets. They offer an ultra-high withstand voltage and high capacitance in a body with the industry’s lowest profile of 3 mm, supporting high-output power delivery through USB Type-C connectors. Mass production for these models is planned to start in December 2025.

These capacitors are ideal for voltage stabilization and noise reduction in power supplies compliant with USB Power Delivery (USB-PD)[1] 3.1. While previous USB-C connectors supplied up to 100 W (20 V/5 A), USB-PD 3.1 expands this to 240 W (48 V/5 A). This enables widespread use of USB-C connectors for high-speed data transfer and rapid charging, and is expected to further expand applications to larger equipment requiring high power output, such as displays.

On the other hand, information and communication equipment such as laptops are increasingly required to be thinner and more compact. Capacitors therefore must combine an ultra-high withstand voltage, high capacitance, and a low profile in order to fit into limited space. Panasonic Industry began mass production of Conductive Polymer Tantalum Solid Capacitors (POSCAP) in 1997 and, as an industry leader, has continuously delivered first-of-their-kind products. Leveraging proprietary powder molding technology and film formation technologies, the company has newly developed two models that achieve both an ultra-high withstand voltage and high capacitance in a package with the industry's lowest profile of 3 mm.

Through these unique device technologies, Panasonic Industry will continue to contribute to enhancing the functionality of electronic equipment, including laptops, while also reducing the environmental impact through smaller, lighter devices and lower material usage.

Key features:

1. Achieves both an ultra-high withstand voltage and high capacitance*2 to support high-output USB Type-C power delivery, in a 3 mm profile—the lowest in the industry*1—enabled by proprietary powder molding and film formation technologies

2. Lineup of USB-PD 3.1-compliant models rated at 50 V and 63 V

3. Contributes to reduced material usage lower environmental impact through low-profile design

*1 As of September 18, 2025, Conductive polymer tantalum solid capacitors with rated voltages of 50 V and 63 V and capacitance of 22 μF or higher (Panasonic Industry data)

*2 USB-Power Delivery 3.1 (180 W/240 W output) compliant high-capacitance conductive polymer tantalum solid capacitors with rated voltages of 50 V and 63 V, and a capacitance of 22 μF or higherDetailed features:

1. Achieves both an ultra-high withstand voltage and high capacitance to support high-output USB Type-C power delivery, in a 3 mm profile—the lowest in the industry—enabled by proprietary powder molding and film formation technologies

To achieve capacitor performance required for USB-PD 3.1 power supplies in a low-profile body, both high capacitance and a high withstand voltage must be ensured, despite their trade-off relationship. High-capacitance tantalum powder is necessary for electrode materials, but its fine particle size makes molding difficult, creating challenges for stable production. Forming a uniform dielectric film on the surface of the electrodes is important for enhancing the withstand voltage. However, since electrodes made with high-capacitance tantalum powder contain extremely small internal pores, dielectric oxide films tend to develop imperfections.

Panasonic Industry overcame these challenges by establishing proprietary technology to mold high-capacitance tantalum powder with uniform density, and by optimizing the film deposition process to create flawless dielectric films. This enabled the development of two new models that combine an ultra-high withstand voltage and high capacitance, meeting the USB-C high-output power delivery requirements in a 3 mm low-profile package.

Cross-sectional view of POSCAP and enlarged view of the inside of the electrode body

2. Lineup of USB-PD 3.1-compliant models rated at 50 V and 63 V

Until now, Panasonic Industry’s POSCAP lineup extended only up to 35 V, with no models compatible with USB-PD 3.1, which extends the rated voltage specification to 36 V (180 W) and 48 V (240 W). The two new models, rated at 50 V and 63 V, each achieve a high capacitance of 22 μF or higher in a package with the industry's lowest profile of 3 mm. The full lineup provides flexibility to meet diverse applications and equipment specifications.

3. Contributes to reduced material usage lower environmental impact through low-profile design

Compared to the industry standard size*3, the new models reduce volume by 25%, contributing to a lower environmental impact through reduced material usage.

*3 Comparison with the industry standard size (7.3 mm × 4.3 mm × 4 mm) of conductive polymer tantalum solid capacitors used in USB-PD 3.1 compliant power suppliesApplications:

Voltage stabilization and noise reduction of USB-PD 3.1-compliant power supplies for laptops, displays, and peripheral equipment

Arc discharge[2] countermeasures for USB-PD 3.1-compliant connectors

Specifications:

Life: 2,000 hours at 105°C; guaranteed operating temperature range: -55°C to 105°C

Ripple current[3]: 100 kHz, 105°C

ESR[4]: 100 kHz, 20°C

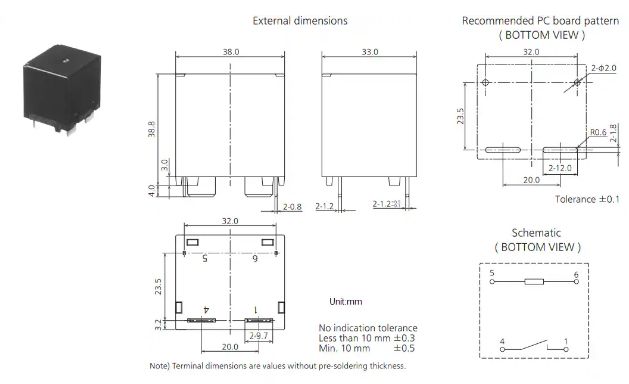

*4 Product dimensional tolerance:

Length (L): ±0.3 mm; Width (W): ±0.2 mm; Height (H): ±0.2 mmTerm descriptions:

[1] USB-PD

The power delivery standards established by the standard-setting organization USB Implementers Forum, Inc. (USB-IF). With the launch of USB-PD 3.1 in 2021, USB Type-C cables and connectors can now deliver up to 240 W of power, supporting a wide range of applications—from smartphones and laptops to larger equipment such as monitors.

[2] Arc discharge

An electric spark or discharge phenomenon that occurs when a high current flows at low voltage in electrical circuits.

[3] Ripple current

When a voltage fluctuation is applied to a capacitor, a corresponding charging or discharging current flows through the capacitor. The current applied to this capacitor is referred to as a ripple current. The higher the ripple current, the higher the allowable current.

[4] ESR (Equivalent Series Resistance)

Represents the value of an internal resistance component that can cause heat generation. Capacitors with lower ESR allow higher ripple currents and provide excellent noise absorption.

在线留言询价

- 一周热料

- 紧缺物料秒杀

| 型号 | 品牌 | 询价 |

|---|---|---|

| RB751G-40T2R | ROHM Semiconductor | |

| MC33074DR2G | onsemi | |

| TL431ACLPR | Texas Instruments | |

| BD71847AMWV-E2 | ROHM Semiconductor | |

| CDZVT2R20B | ROHM Semiconductor |

| 型号 | 品牌 | 抢购 |

|---|---|---|

| TPS63050YFFR | Texas Instruments | |

| ESR03EZPJ151 | ROHM Semiconductor | |

| BP3621 | ROHM Semiconductor | |

| BU33JA2MNVX-CTL | ROHM Semiconductor | |

| IPZ40N04S5L4R8ATMA1 | Infineon Technologies | |

| STM32F429IGT6 | STMicroelectronics |

- 周排行榜

- 月排行榜

AMEYA360公众号二维码

识别二维码,即可关注

请输入下方图片中的验证码: